Customized service

Service Introduction

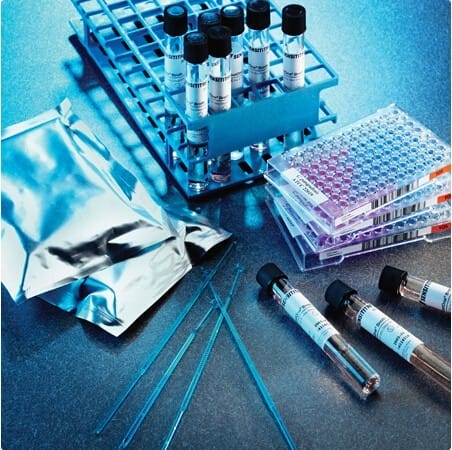

We provide organic custom synthesis services for a wide range of compounds and intermediates, including the synthesis of electronic chemicals. We are able to synthesize biologically active compounds with weights ranging from milligrams to kilograms through the total synthesis of intermediates, synthetic building blocks, reference compounds and impurities. We have successfully completed a large number of orders on time for custom chemical synthesis involving a variety of reaction types including, but not limited to, chiral synthesis and splitting, oxidation, reduction, condensation, nitrosation, bromination, and more. Our services also include purification and refinement of chemicals and compounds under harsh conditions such as high-pressure hydrogenation, oxygen-free and water-free environments, ultra-low temperatures, and highly corrosive environments.

Service Advantages

technological leadership

We have an experienced and pioneering R&D team of professionals, including several PhDs and Masters in chemistry, who specialize in complex chemical synthesis problems.

Perfect quality management

The ISO9001:2015 certified quality management system ensures that every step of the process, from raw material procurement to the final product, is subject to strict quality control, realizing high product quality and consistency.

Professional project management

Professional project management ensures that every step of the process, from requirements communication to final delivery, is finely controlled, resulting in efficient project execution and high quality results.

Tailor-made production solutions

Tailored production solutions ensure that synthesis needs from milligrams to kilograms can be precisely met, enabling efficient, flexible and cost-optimized production processes.

Question&Answer

What types of chemical reactions can the company handle?

We specialize in a range of chemical reactions including, but not limited to, organometallic reactions involving butyl lithium, diazotization reactions, reduction reactions, nitration reactions, isocyanate reactions, diazomethane preparation and application, Foucault reactions, mixed anhydride preparation, and oxidation reactions.

Can you customize solutions for specific applications?

Absolutely. Our team of experts works closely with our customers to gain an in-depth understanding of their specific needs and develop customized solutions that meet the requirements of the particular application.

What is a typical timeline for a custom project?

The timeline varies depending on the complexity of the project. It usually includes initial discussions and evaluation, design and quotation, development and sample preparation, and finally sample delivery and acceptance. We provide a detailed timeline during the design phase.

Do you offer quality assurance measures?

Yes. We implement strict quality control procedures throughout the process, from the selection of raw materials to the testing of finished products, to ensure compliance with international standards.

How to protect intellectual property (IP)?

We take the protection of intellectual property rights very seriously. Non-disclosure agreements are signed at the beginning of a project to protect our clients’ intellectual property. In addition, we have strict internal policies to safeguard proprietary information.

What support is provided after delivery?

We provide comprehensive post implementation support including technical advice, troubleshooting and ongoing partnership counseling to ensure successful implementation of our products.

Is there a limit to the size of production?

Our microchannel technology allows scaling up from lab-scale production to commercial-scale manufacturing. We can adapt our manufacturing process to different production volumes.

How do you ensure consistency between batches?

We use standardized operating procedures and continuous monitoring systems to maintain consistent quality. Each batch undergoes rigorous testing to ensure compliance with high standards.

Contact Us

If you cannot find the product you need, please leave a message and let us know. We will reply as soon as possible to provide you with assistance!